Electrical Components

02

To ensure the hardware works smoothly, we designed and modified some components based on specific needs. The details of these custom components are shown below.

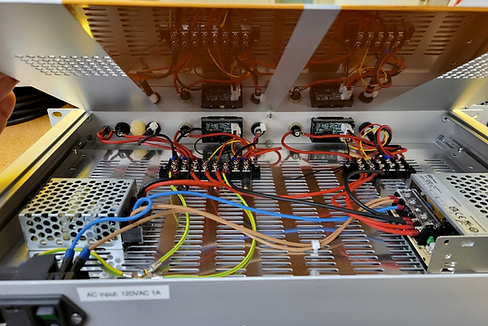

Low Voltage Power Supply Chassis:

The laser box system (Part of the UV Laser Calibration System) is powered by a custom-built low-voltage (LV) chassis designed to supply the necessary DC power for its components, including a reference laser, attenuator, and photodiodes. The chassis incorporates two regulated power supplies, providing 12V and 5V outputs to meet the varied requirements. It features a robust design with AC input connections, grounding for safety, and terminal blocks for distributing DC power. The system includes fuses for protection, adjustable voltage options, and safeguards against over-current and short circuits. Halogen-free cables transmit power to the components, ensuring safe and reliable operation. Additionally, monitoring tools like a voltmeter ensure stable supply, and the alignment laser is equipped with a switch for controlled use. These units are fully built to meet OSHA-NRTL requirements and have received operational readiness clearance from Fermilab's ES&H team.

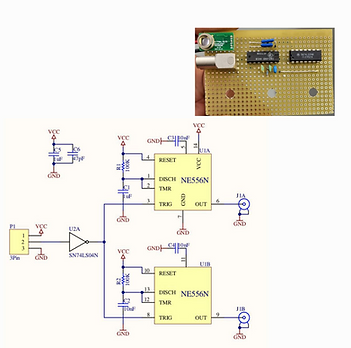

Trigger Module:

The custom-built trigger module is equipped with photodiode modules with dual outputs specifically designed for triggering purposes. These modules detect laser beams within a spectral range of 450-1050 nm, generating signals with a 5V amplitude and a duration of 5-30 µs. The signals are processed through an NE556 IC chip, which contains two NE555 timer modules. The first timer generates a 300 ms wide pulse, which is sent to the Feedthrough and subsequently to TMC boxes via a DB15 communication cable. The second timer produces a 30 µs signal, which is processed through a NIM crate and then delivered to the data acquisition (DAQ) system.

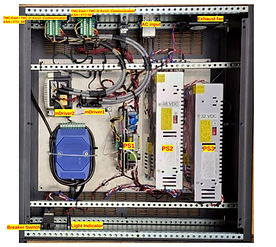

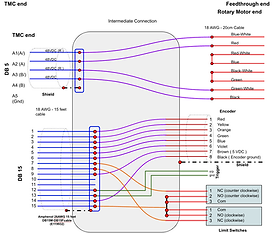

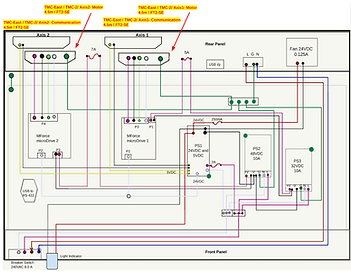

Motor controller and encoder:

The motor controller or TMC boxes are key components that ensure the precise operation of the laser system. The motor controller regulates stepper motors, and readback encoder values to enable accurate positioning and smooth movement for laser alignment. The TMC boxes handle both timing and motor control, receiving trigger signals and synchronizing motor actions with the laser firing sequence. These modified boxes are designed for seamless integration with the system, ensuring reliable performance and smooth coordination between components for efficient laser calibration and precise position reading.